PE foam is revolutionizing the packaging industry with its innovative uses and numerous benefits. This versatile material has sparked a wave of change, offering solutions that go beyond traditional packaging methods. Imagine a world where packaging not only protects but also enhances the products it holds, like a superhero swooping in to save the day. PE foam is that hero, bringing a new level of efficiency and effectiveness to the packaging world.

Picture a delicate glass ornament being shipped across the country. With PE foam cushioning its journey, it arrives unscathed, as if it had been cradled in the softest of clouds. This is the magic of PE foam – its ability to cushion fragile items and ensure they reach their destination intact. It’s like giving your products a protective bubble wrap that molds perfectly to their shape, safeguarding them from the bumps and jolts of the shipping process.

But the benefits of PE foam go beyond protection. It also excels in insulating products, keeping them safe from extreme temperatures during transit. Just like a cozy blanket on a cold winter night, PE foam wraps your products in warmth, ensuring they arrive in perfect condition, no matter the weather outside. And the best part? It does all this while remaining lightweight and durable, reducing shipping costs and environmental impact.

PE foam packaging is not just a game-changer in terms of functionality; it’s also a sustainability superstar. By being recyclable, energy-efficient in production, and eco-friendly, PE foam is paving the way for a greener future in packaging. It’s like a breath of fresh air in a world filled with waste, offering a solution that is both effective and environmentally conscious.

As we look to the future of packaging, PE foam stands at the forefront of innovation. With advanced design capabilities, customization options, and the potential for integration with smart packaging technologies, the possibilities are endless. It’s like watching a fireworks display, each burst of color representing a new breakthrough in PE foam packaging technology. The future is bright, and PE foam is leading the way towards a more efficient, sustainable, and exciting packaging industry.

Benefits of PE Foam Packaging

When it comes to packaging materials, PE foam stands out as a game-changer. Its benefits go beyond just protecting the contents of a package; it revolutionizes the entire packaging industry. Let’s delve into the myriad advantages that PE foam brings to the table.

First and foremost, one of the key benefits of PE foam packaging is its exceptional cushioning properties. Fragile items are safeguarded against impacts and shocks during transit, ensuring they reach their destination intact. This reliability in protection minimizes the risk of damage, ultimately saving both businesses and customers from the woes of broken goods.

Moreover, PE foam excels in insulating products. Whether it’s maintaining the temperature of perishable goods or protecting sensitive electronics from extreme heat or cold, PE foam serves as a reliable barrier. This insulation capability not only preserves the quality of the products but also enhances their shelf life.

Another significant advantage of PE foam is its lightweight yet durable nature. Unlike bulky and heavy packaging materials, PE foam offers a lightweight solution without compromising on strength. This balance between weight and durability translates to cost savings in shipping, as lighter packages incur lower transportation expenses.

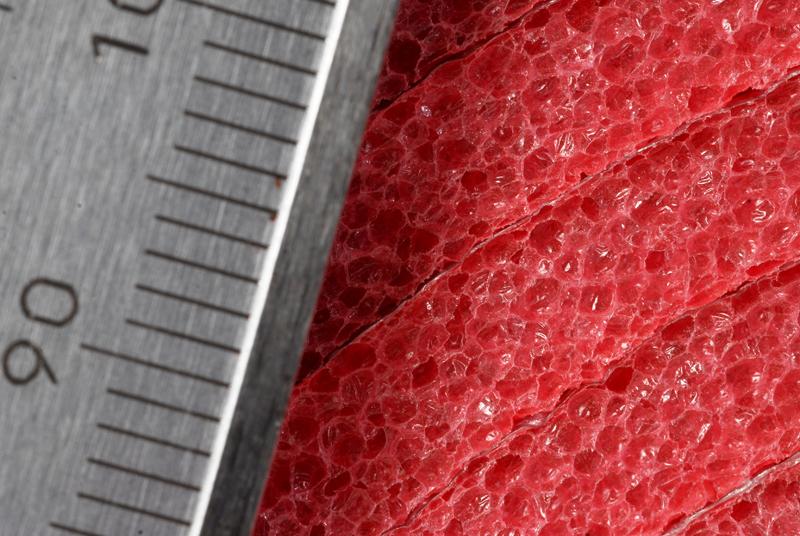

Furthermore, the versatility of PE foam packaging is unparalleled. It can be molded and shaped to fit various product shapes and sizes, providing a customized packaging solution. This adaptability ensures that each item is snugly secured within the package, reducing the risk of movement and potential damage during handling and shipping.

Environmental Sustainability

When it comes to packaging materials, PE foam stands out not only for its protective properties and versatility but also for its significant impact on environmental sustainability. Let’s delve into how PE foam packaging contributes to the eco-friendly efforts of the packaging industry.

One of the key aspects of PE foam packaging that makes it environmentally sustainable is its recyclability. Unlike traditional packaging materials that end up in landfills, PE foam can be recycled and reused, reducing the overall environmental footprint. This recyclability factor plays a crucial role in reducing waste and promoting a more circulatory economy.

Moreover, the production process of PE foam is energy-efficient, requiring less energy compared to other packaging materials. This not only helps in lowering carbon emissions but also contributes to overall energy conservation efforts in the industry.

Another significant aspect of PE foam packaging in terms of sustainability is its eco-friendly characteristics. PE foam is known for being non-toxic and chemically inert, making it a safe choice for packaging various products without posing harm to the environment.

In addition to its recyclability and energy efficiency, PE foam packaging also offers a lightweight yet durable solution. This combination not only reduces the overall weight of packaged goods, leading to lower shipping costs and less fuel consumption

Future Trends and Innovations

When it comes to the future trends and innovations in PE foam packaging, the possibilities seem as vast as the horizon. Picture a world where packaging not only protects your products but also interacts with consumers, providing real-time information and enhancing user experience. This isn’t just a dream; it’s the direction in which PE foam technology is heading.

Imagine a scenario where your package communicates with you, guiding you on how to recycle it properly or letting you know if the product inside has been tampered with. This level of smart packaging is becoming more achievable with the integration of sensors and RFID technology into PE foam materials.

Furthermore, customization is key in the future of packaging. With PE foam, intricate designs and tailored solutions are within reach. Whether it’s creating packaging that perfectly fits the contours of a delicate object or incorporating branding elements seamlessly, the flexibility of PE foam allows for endless creative possibilities.

While coming to the end of our article, do not forget to review Durfoam‘s physically cross linked polyethylene foam, chemically cross linked polyethylene foam, polyethylene foam services.

Moreover, the potential for enhancing the protective properties of PE foam is constantly evolving. From shock-absorbing capabilities to temperature regulation features, the future holds innovations that will revolutionize how we think about packaging materials.

In summary, the future of PE foam packaging is not just about wrapping products; it’s about creating an experience. It’s about sustainability, innovation, and pushing the boundaries of what packaging can achieve. As technology advances and consumer demands evolve, PE foam is poised to lead the way in shaping the packaging industry of tomorrow.