When it comes to materials, the debate between PE foam and traditional options like wood and metal is more than just a technical discussion; it’s a clash of modern innovation versus time-tested reliability. Have you ever wondered why PE foam has become such a popular choice in industries ranging from packaging to construction? Its lightweight nature and flexibility make it a game-changer, but does it really stack up against the robust qualities of traditional materials?

PE foam boasts remarkable properties that set it apart. Imagine a material that can absorb shock, insulate against temperature fluctuations, and still remain incredibly lightweight. This is why you’ll often find it in packaging solutions, providing protection for fragile items during shipping. On the flip side, traditional materials bring their own strengths to the table. Think about the sturdy feel of wood or the sleek finish of metal. These materials have been around for centuries, offering not only strength but also an aesthetic appeal that many find hard to resist.

In the end, the choice between PE foam and traditional materials depends on your specific needs. Are you looking for something that’s easy to handle and offers excellent cushioning? Or do you prefer the classic look and durability of wood or metal? Understanding the unique advantages of each can help you make an informed decision that meets your project requirements.

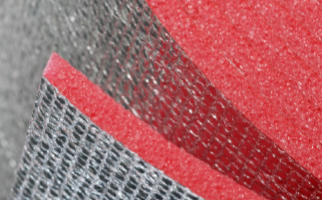

Properties of PE Foam

PE foam, or polyethylene foam, is a game changer in the world of materials. Its lightweight nature makes it a favorite among manufacturers who need to keep shipping costs low without sacrificing quality. Imagine carrying a feather versus a brick; that’s the difference in weight when comparing PE foam to traditional materials!

One of the most impressive characteristics of PE foam is its flexibility. This material can easily adapt to various shapes and sizes, making it ideal for packaging fragile items. Think of it as a protective cushion that hugs your valuables, preventing any damage during transportation. Additionally, PE foam is durable, resisting wear and tear while providing excellent insulation properties. It acts like a warm blanket, keeping your products safe from temperature fluctuations.

Moreover, PE foam is resistant to moisture and chemicals, which means it can withstand harsh environments without deteriorating. This property is crucial in industries such as construction and automotive, where exposure to elements is inevitable. In summary, the unique properties of PE foam not only enhance its performance but also make it a versatile choice across various applications.

Advantages of Traditional Materials

When it comes to traditional materials like wood and metal, their timeless appeal and robustness are hard to ignore. These materials have been the backbone of construction and manufacturing for centuries, proving their worth in various applications. For instance, wood not only offers a natural aesthetic that can enhance the beauty of any space but also provides excellent insulation properties. It’s like wrapping your home in a warm, cozy blanket! On the other hand, metal brings unmatched strength and durability, making it a go-to choice for structural applications.

One of the most significant advantages of traditional materials is their sustainability. Wood, when sourced responsibly, is a renewable resource, while metals can be recycled endlessly without losing their properties. This makes them not just environmentally friendly but also economically viable. Imagine building a home that not only stands the test of time but also contributes to a healthier planet!

Moreover, traditional materials often come with a rich history and cultural significance. They can tell stories of craftsmanship and tradition, something that modern materials sometimes lack. For example, consider a beautiful wooden table passed down through generations; it’s not just a piece of furniture, but a family heirloom filled with memories. In summary, while modern alternatives like PE foam have their advantages, traditional materials hold their ground with strength, beauty, and sustainability.

Applications in Various Industries

When it comes to applications, both PE foam and traditional materials shine in their own unique ways. In the construction industry, for example, PE foam is a game changer. Its lightweight and flexible nature makes it an ideal choice for insulation and soundproofing, while traditional materials like wood and metal are often favored for structural integrity and durability. It’s like comparing a nimble dancer to a sturdy oak tree; both have their roles but excel in different areas.

In the automotive sector, PE foam is often used for interior padding and sound dampening, providing a comfortable ride without adding excessive weight. Meanwhile, traditional materials such as steel and aluminum are still the backbone of vehicle frames, offering strength and safety. This combination of materials ensures that cars are not only sleek but also robust.

Consumer goods also showcase the versatility of these materials. PE foam is widely used in packaging, protecting fragile items during transit, while traditional materials like glass and ceramics are preferred for their aesthetic appeal and timelessness. Just think of it this way: PE foam is the bubble wrap of the modern age, ensuring your precious items arrive safe and sound!

In summary, both PE foam and traditional materials have their place across various industries, each offering distinct advantages that cater to specific needs. Understanding these applications can help you make informed decisions, whether you’re in construction, automotive, or retail.

While coming to the end of our article, do not forget to review the following service pages of Durfoam: